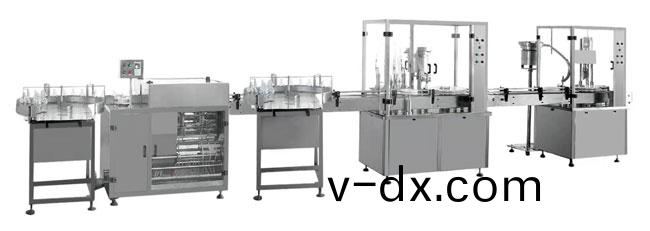

Introduction of large-capacity filling and capping machine:

GYGX large-capacity filling and capping machine is a filling host for 50-250ml reagents, oral liquids, etc. in the filling production line. It is mainly used for 50ml-250ml liquid filling. Partial tracking filling, not easy to generate foam, high cover rate.

This machine is used for filling in pharmaceutical factories. The whole machine can complete the processes of unscrambling, conveying, quantitative filling, corking, or capping, and capping. All parts that come into contact with medicines are made of stainless steel or PTFE. Usually it can be used alone or connected with related machinery to achieve a consistent production line. It is suitable for automatic filling, plugging, capping or capping operations in general chemicals, pharmaceuticals, food, cosmetics, cleaning supplies, etc.

The whole machine adopts frequency conversion speed regulation, equal division plate positioning, plunger pump filling, and single-head screw capping; it has protection functions such as no bottle and no filling to ensure the normal operation of production. The machine has a high degree of automation, stable operation, very convenient operation, and meets the requirements of GMP.

Parameters of large-capacity filling and capping machine:

1. Production capacity: 20-120 bottles/min

2. Applicable bottles: glass bottles, plastic PET bottles, vials

3. Number of filling heads: 2-16 heads

4. Number of capping heads: 1-4 heads

5. Power supply: 380V 50Hz three-phase four-wire system